MagnusHD Barrel for AEG -260mm

With inheriting the performance of a 6.23 diameter Magnus Barrel and its high-performance teflon coating, we managed to reduce the resistance to BB bullet rotation and straight movement.

The ORGA Magnus Barrel series, the 6.23mm and 6.13mm, are the industry’s highest diameter for AEG inner barrels. Especially ORGA’s custom products are optimal for those who hope to achieve high accuracy shootings.

The 6.23mm is often used for power customs (Japan 1J regulations) . By combining it with a high spring rate, it is possible to make some use to it.

Although, since the 6.23mm has a wide inner diameter, we did experience some difficulties with some guns. To name a few, rifles that had less than 7.5 inches (MP5 or Kurz) were not compatible since their inner barrels are shorter. For these rifles, we had to use a stronger spring to make up for the lost power.

It goes without saying that when the springs are stronger, a more powerful battery has to be adopted as well.

The HD Barrel was created to avoid these problems all together.

Not only is this HD barrel compatible with short guns, but also with Tokyo Marui Next Gen AEGs, which will sure improve the performance. Thanks to the introduction of HD barrels, strong springs are no longer a necessity and can increase range as well as accuracy.

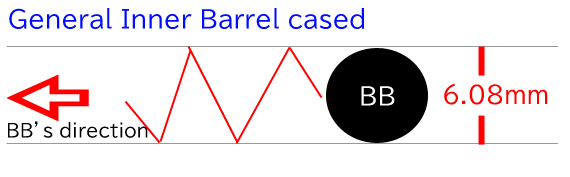

The following describes the operation when using a barrel with a wide inner diameter.

Friction may occur if the inner barrel’s diameter is narrow. When the inner barrel is narrow, genuine barrels and tight barrels, anything less than a 6.08mm diameter, increases the number and time the airsoft pellets hit the tube wall leading to frictions.

On the other hand, if you use a long inner barrel for the AEG, the initial speed decreases when applying hop-up. This is related to the inner tube friction explained above.

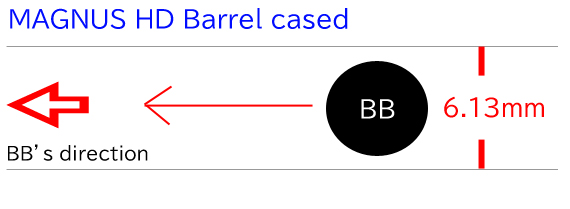

The MAGNUS barel has a diameter of 6.13mm which can reduce the friction enabling the airsoft pellet to fire smoothly. This creates a higher shooting accuracy.

It can also be optimal for high cycle AEGs.

It can also be optimal for high cycle AEGs.

The primary reason for High cycle AEG’s malfunction are airsoft jams. If the inner barrel’s diameter is too small, it could lead to a piston crash or a gear crash when using low quality pellets or bio BB pellets that have been opened and kept away.

This happens because the clogged bullets block the air (same condition as blocking the syringe outlet with your finger), causing the sector gear to rotate without the piston moving forward.

The 6.13 mm HD barrel has a wider diameter, which will prevent airsoft jams.

The performance is also enhanced since the barrel is coated with lubricated teflon making the pellets fire smoothly.

Cutting the upper part to reduce the distortion of the bullet feed

The Magnus barrel has been made lower on the left side of the HOP-Up rubber band. This allows the Hop-Up’s lower part and packing’s gap to be pulled, preventing the bullet feed’s rubber from pulling when Hop-Up is applied.

This can be beneficial since the shape of the bullet feed do not change making it airtight.

Packing attachment with horizontal/ vertical slit process

Packing attachment with horizontal/ vertical slit process

There are two slits on the left and right sides of the barrel. It can be attached to the barrel by rotating the chamber packing 90 degrees. A general packing has a protrusion on the inside. Although, for a airsoft pellet, it can achieve higher shooting accuracy with a flat hop-up packing.

Before, each player would turn the packing inside out, scraping the protrusion off to make a flat hop. Although this created problems since the processed hop would be rough or uneven from the other surface, leading to low performance.

In addition, forcibly turning it inside out caused the packing itself to grow, leading to leaks of air.

Just rotate the packing and attach!

Just rotate the packing and attach!

As described above, a perfect surface HOP can be created by simply aligning the inner slits of the packing with the left and right slits without having to scrape the packing inside.

ANYONE/ WITHOUT ALTERCATION/ HIGHER QUALITY than ProShop

With inheriting the performance of a 6.23 diameter Magnus Barrel and its high-performance teflon coating, we managed to reduce the resistance to BB bullet rotation and straight movement.

The ORGA Magnus Barrel series, the 6.23mm and 6.13mm, are the industry’s highest diameter for AEG inner barrels. Especially ORGA’s custom products are optimal for those who hope to achieve high accuracy shootings.

The 6.23mm is often used for power customs (Japan 1J regulations) . By combining it with a high spring rate, it is possible to make some use to it.

Although, since the 6.23mm has a wide inner diameter, we did experience some difficulties with some guns. To name a few, rifles that had less than 7.5 inches (MP5 or Kurz) were not compatible since their inner barrels are shorter. For these rifles, we had to use a stronger spring to make up for the lost power.

It goes without saying that when the springs are stronger, a more powerful battery has to be adopted as well.

The HD Barrel was created to avoid these problems all together.

Not only is this HD barrel compatible with short guns, but also with Tokyo Marui Next Gen AEGs, which will sure improve the performance. Thanks to the introduction of HD barrels, strong springs are no longer a necessity and can increase range as well as accuracy.

The following describes the operation when using a barrel with a wide inner diameter.

Friction may occur if the inner barrel’s diameter is narrow. When the inner barrel is narrow, genuine barrels and tight barrels, anything less than a 6.08mm diameter, increases the number and time the airsoft pellets hit the tube wall leading to frictions.

On the other hand, if you use a long inner barrel for the AEG, the initial speed decreases when applying hop-up. This is related to the inner tube friction explained above.

The MAGNUS barel has a diameter of 6.13mm which can reduce the friction enabling the airsoft pellet to fire smoothly. This creates a higher shooting accuracy.

It can also be optimal for high cycle AEGs.

The primary reason for High cycle AEG’s malfunction are airsoft jams. If the inner barrel’s diameter is too small, it could lead to a piston crash or a gear crash when using low quality pellets or bio BB pellets that have been opened and kept away.

This happens because the clogged bullets block the air (same condition as blocking the syringe outlet with your finger), causing the sector gear to rotate without the piston moving forward.

The 6.13 mm HD barrel has a wider diameter, which will prevent airsoft jams.

The performance is also enhanced since the barrel is coated with lubricated teflon making the pellets fire smoothly.

Cutting the upper part to reduce the distortion of the bullet feed

The Magnus barrel has been made lower on the left side of the HOP-Up rubber band. This allows the Hop-Up’s lower part and packing’s gap to be pulled, preventing the bullet feed’s rubber from pulling when Hop-Up is applied.

This can be beneficial since the shape of the bullet feed do not change making it airtight.

Packing attachment with horizontal/ vertical slit process

There are two slits on the left and right sides of the barrel. It can be attached to the barrel by rotating the chamber packing 90 degrees. A general packing has a protrusion on the inside. Although, for a airsoft pellet, it can achieve higher shooting accuracy with a flat hop-up packing.

Before, each player would turn the packing inside out, scraping the protrusion off to make a flat hop. Although this created problems since the processed hop would be rough or uneven from the other surface, leading to low performance.

In addition, forcibly turning it inside out caused the packing itself to grow, leading to leaks of air.

Just rotate the packing and attach!

As described above, a perfect surface HOP can be created by simply aligning the inner slits of the packing with the left and right slits without having to scrape the packing inside.

ANYONE/ WITHOUT ALTERCATION/ HIGHER QUALITY than ProShop